Corian Worktops have been supplied in the industry for over 50 years, having the esteemed accolade of being the original solid surface material. Corian has a unique receptiveness to thermoforming, which allows for all manner of unconventional and artistic curves to be produced in seamless fabrications. Worktops made from Corian are seamless, hardwearing, water resistant and warm to the touch.

The original solid surface material, Corian®, was specifically designed as a work surface when it was first introduced in 1967. With its balance of beauty and performance, Corian® worktops lend themselves to imaginative uses, innovative designs and enduring work surface applications. Corian® worktops are warm to the touch, have seamless joints, excellent impact, stain and water resistance. Corian® work surfaces come with a 10 year Manufacturer’s Limited Warranty, backed by the DuPont™ Quality Network.

- 10 year Limited Manufacturer’s Warranty backed by DuPont™

- Introduced in 1967 it is the original solid surface material

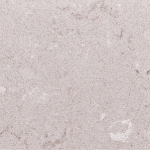

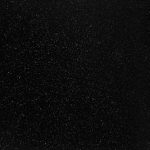

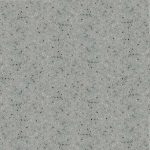

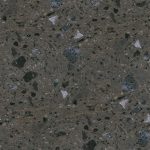

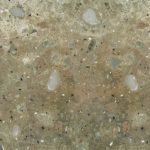

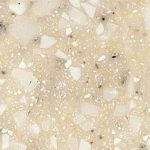

- Worktops available in a wide selection of colours

- Solid, homogeneous and non-porous

- Worktops cannot delaminate or rot under pressure

- Difficult to stain

- Worktops are easy to clean &maintain

- Warm & inviting to the touch

- Worktops have excellent impact resistance

- Inconspicuous, unobtrusive and seamless joints

- Infinite design possibilities

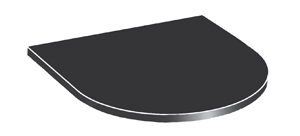

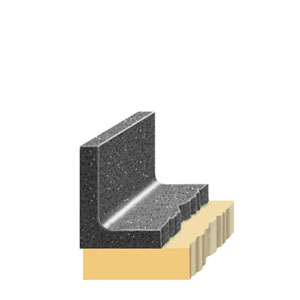

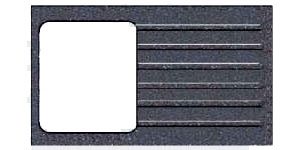

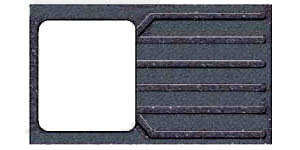

End Panels

Shoulder Housing Joint

The end panels will be of a shoulder housing joint configuration to produce a flush fitting appearance. The height of the end panel will be manufactured with a 10mm excess, allowing it to be scribed on site.

Corian Upstands are manufactured along with the worktop to provide a seamless join between the two.

On installation, we endeavour to keep as close as possible to the line of the wall, but due to natural flexing of structures over time, there may be gaps between 2mm and 4mm at the back of your worktop. Such gaps may be more prominent in older buildings, and for this reason we recommend that plastering or tiling should be ideally completed after the worksurface installation.

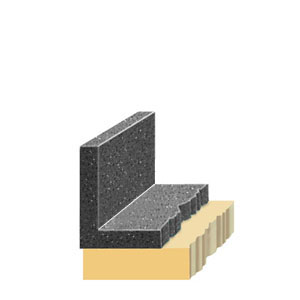

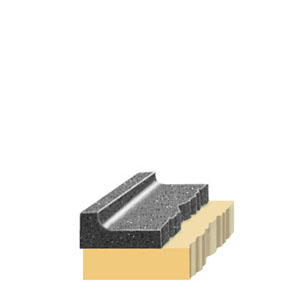

We have 3 variants of upstand typically available with Corian worktops; Square, 10mm Coved and 50mm Coved.

(Above: Square, 10mm Coved and 50mm Coved Corian Upstands, respectively.)

The compulsory method for installing square hobs is the high-strength cutout patented by Dupont™. Hobs must be integrated into a Corian® worksurface, according to specified guidelines.

When deciding on the layout of your cutouts, please bear the following in mind:-

- A minimum of 120mm is required between two hob cutouts

- A minimum of 50mm from the cutout to the front edge is required

- A minimum of 50mm is required between sink cutouts.

Please specify the preferred undermounting of stainless steel sinks.

Silicone sealant my be rendered ineffective when plumbing the sink in, it is important that the sink is re-sealed by the plumber, or the 12 months guarantee will be invalid.

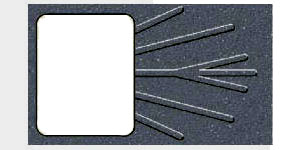

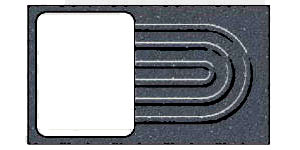

- Type A, B & C have a 1 – 5mm gradient

- Type D, E are flat with 3mm flat

- Type F is flat with a 3mm recess

A small amount of standing water will be retained in drainer grooves, after the majority of the water has drained away, this should be wiped clear to avoid water residue marking the worksurface.

When we at Trade Price Worktops supply a worktop, we include with every order our Care & Maintenance kit which includes everything you need to keep your worktop in first class condition. Follow the instructions within for a trouble free, great looking worktop. Our detailed care & maintenance brochure can be downloaded online by clicking here. For additional care kit supplies, please contact our sales team.

For additional care kit supplies, please contact our sales team.

Introduction

Corian® is a solid surface material made from 1/3 acrylic resin and 2/3 mineral filler. It is used as a decorative material in a variety of applications, such as kitchens and bathrooms in both commercial and residential environments. Corian® is supplied in sheets which can then be fabricated into worktops, vanity tops, showers and cladding – which will offer versatility, functionality and durability.

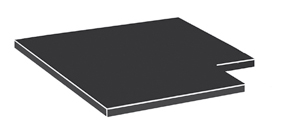

Joints

Joints are inconspicuous and unobtrusive providing a seamless worksurface. Due to the level of pigment in the material, joints can be blended to insignificance.

Thermal expansion

Due to thermal expansion Corian® can expand up to 1mm per metre. A gap of at least 3mm should be left at each end of the worktop when fitted and filled with decorators caulk. When Corian® is joined to other materials (such as glass, steel or wood) an elastic type of adhesive, for example polyurethane is required for expansion.

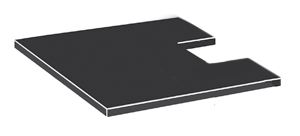

Hob & Sink cutouts

The compulsory method for installing square hobs is the high-strength cutout patented by Dupont. Hobs must be integrated into a Corian® worksurface according to specified guidelines. Where a Corian® splash back or wall cladding is installed a gap of 50mm (minimum) is required behind an electric hob or 100mm (minimum) for a gas hob. A ‘breakfront’ may be necessary to accommodate this requirement. There must be a minimum of 50mm from the cutout to the front of the worktop and a gap of 120mm between heated cutouts.

A minimum of 50mm is required between two sink cutouts. Sink cutouts must be placed a minimum of 50mm from the worktop front edge. This is required under terms of the product warranty.

If a waste disposal unit is fitted to an undermounted sink after installation, additional support will be required, otherwise your warranty may be invalidated.

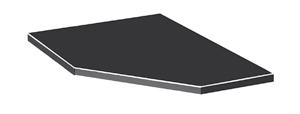

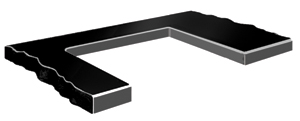

Upstands

There are two types of upstand available.

- Square Corian® upstands are fixed on site, with Corian® glue or silicone.

- Coved Corian® upstands are manufactured and fixed in the factory.

Due to manufacturing constraints there may be gaps as these upstands are manufactured in a straight line. This type of upstand is not suitable for walls where there are large variations in the wall profile. Plastering or tiling should ideally be completed after the worksurface installation.

Tolerance

Tolerance in Corian® is ±2mm

Overhangs and supports

Any overhang extending more than 300mm should be supported.

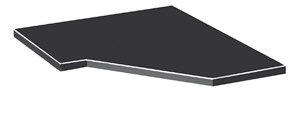

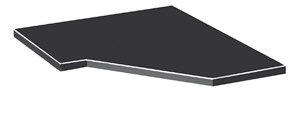

Internal radius

The minimum internal radius is 80mm. Thermoforming to achieve a smaller radius can result in “bleaching” of the colour. To achieve a radius smaller than 80mm Corian® may have to be laminated, this may be visible in larger particled Corian® colours.

Scratches

Corian® is scratch resistant but not scratch proof; the use of chopping boards and/or pastrymates is recommended. Dark, heavily pigmented colours will show scratches, dust and ordinary wear and tear more readily than lighter, textured forms.

Staining

While most tough stains can be buffed away, a level of care and maintenance is required, as spills should be cleaned up immediately.

Repairable

Corian® surfaces can easily be repaired. Using an ordinary abrasive cleaner and a scouring pad the surface may be fully restored to its original appearance.

Hygienic

Corian® is a non-porous material. Naturally resistant to mould, bacteria and mildew, Corian® surfaces have been certified by an independent laboratory as a hygienic material, according to the international norm DIN EN 1SO 846.

Choose from the complete collection...